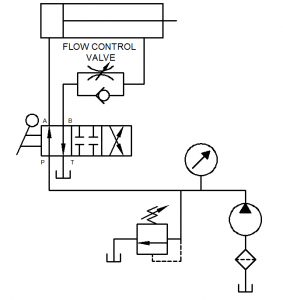

The application of flow control valve (meter-out circuit)

Objective: To become more knowledgeable with the hydraulic system. Flow control valve is controlling the rate of flow in a hydraulic circuit; it’s possible to control the speed of hydraulic cylinder. A cylinder is speed is determined by its size and the flow rate of the oil going to or out of it. A large diameter cylinder would hold more oil and take longer to complete its stroke; a smaller the cylinder would move faster. Changing the flow rate from the pump would also change the extension time of the cylinder.

Metering out has the advantage of maintaining back pressure on the lower pressure side of the cylinder. This prevents sudden extension or retraction of the cylinder if the load reverses.

Procedure/ demonstrations:

1. Make sure relief valve #2 is set at 500 Pound per square inch (PSI). Globe valve # 3 is open, Needle valve #4 is closed, and Needle vale #6 is open.

2. At manifold pressure gauge #5 used the hoses connect to direction valve # 7.

3. Two-output gauge at the direction valve # 7 use the hoses one connect to Extend hydraulic cylinder #12 and another one connect to flow control valve # 10, then at out put from flow control used the hose connect with retract cylinder (in this case we called meter-out circuit) also, connect gauge #16 to rod end of cylinder #12 as show above.

4. Make sure direction valve # 7 is in center or neutral position.

5. Fully open Flow control valve #10 (clockwise rotation of adjusting knob).

6. Turn on power unit.

7. Extend and retracted piston rod of # 12

8. The pressure reading on gauge # 15 and #16 represent while piston rod is moving.

9. With piston rod retracted, fully close flow control valve #10 (counterclockwise rotation of adjusting knob).

10. Shift direction valve # 7 to extend piston rod and slowly open flow control valve #10 until piston rod start moving slowly. The pressure in cap end of cylinder #12 indicates relief valve setting even though there is no external resistive load on piston rod of cylinder. The pressure in rod end gauge #16 higher than relief valve setting.

11. Turn off power unit.

Discussion:

The flow control is on the out let side of the cylinder to control the flow coming out. This is known as a meter-out circuit. A cylinder is speed is determined by its size and the flow rate of the oil going to or out of it. A large diameter cylinder would hold more oil and take longer to complete its stroke; a smaller the cylinder would move faster. Changing the flow rate from the pump would also change the extension time of the cylinder. Changing either the cylinder or pump size to regulate speed would be impractical, especial if a change were desired in mid-stroke. If the flow control were closed completely. In this case we should known about the retraction of the cylinder control by flow control valve. The oil could not exhaust from the cylinder and it could not move. Regulating the size of the open control flow rate, and therefore the speed, of the cylinder.

Conclusion:

The meter-out circuit can be very accurate, but are not efficient. The meter-out circuit can control overrunning as well as opposing loads while the other one method must be used with opposing loads only. The choice of flown control valve method and the location of the flow control in the circuit are dependent on the type of application being controlled.