Objectives:

- Familiarize students with the the purpose and function of a CMM machine

- Develop an understanding of how CMMs define point geometry

- Reinforce spatial visualization skills

- Introduce students to the Dimensional Measuring Interface Specification (DMIS) language

- Introduce students to PC-DMIS software

Procedure:

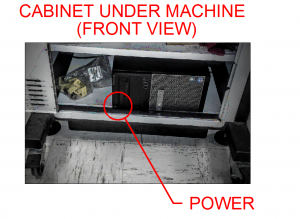

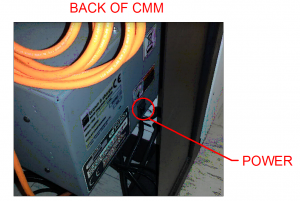

- Power up PC

- Power up CMM

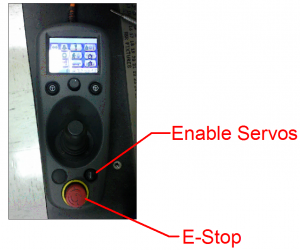

- Make sure the E-stop is out by twisting it gently.

- Start the servos by pressing the “Enable Servos” button.

- Hold it down until you hear the a “click.”

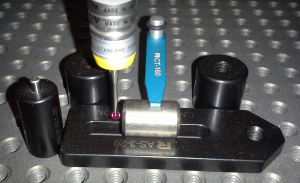

- Be sure your tool stack looks like the photo below and the probe points straight down.

If it does not, SEE YOUR INSTRUCTOR. - Start PC-DMIS.

- You will need to click “yes” at the dialog box that appears.

- Start a new program.

- Be aware that PC-DMIS defaults to opening an existing file. Cancel this dialog box.

- Select INCH units.

- Select “Lab1 Probe”

- Click OK to home the machine

- Jog the machine by holding either “T” button on the pendant while jogging the joystick.

- USE “TURTLE MODE” when within 3″ of the part.

- Ensure that the part is set up as shown here:

- Enable the “Measured Features” toolbar.

- Select “Guess Mode.”

- Probe a single point on one of the flat ends of the cylinder.

- Press “ENTER” on the teach pendant.

- You should hear a chime.

- A point entity should appear in the DMIS program.

- Move the probe to the other end and probe another point there.

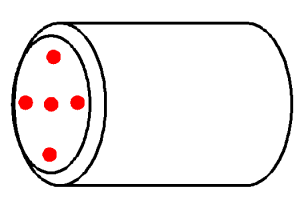

- Now probe a series of 5 points on one end as shown:

- If guess mode creates an entity other than a plane, delete all the points (and the entity) and re-probe.

- Modify the view to show that the two points lie on the two planes.

- Insert a distance dimension to find the distance between the two planes.

- The distance should be 3D

- The nominal value is .75

- The + tolerance is 0.001 and the minus is 0.001

- Save your file in the directory defined by your instructor.

Recommended Reading: