Reading Assignment

- 24.1 Introduction to Milling

- 24.2 Fundamentals of Milling Processes

- 24.3 Milling Tools and Cutters

- 24.4 Machines for Milling

Recommended Links

- Study Guide – Milling

- Crash Course in Milling Video Series (Highly recommended)

Outline

Milling Machines

Milling Methods

Peripheral Milling

Also called “slab millling”

Milled surface is parallel to cutter axis

Cuts with the periphery of the cutter

Milled surface is generally at right angle to axis of the cutter.

Should be applied where possible.

End Milling

Other Milling Operations

Straddle Milling

Gang Milling

Gear Milling (see also Gear Hobbing)

Cam Milling

Thread Milling

Holemaking

Tapping

Up and Down Milling

Main difference is in the cutting forces generated.

- Up milling opposes the thrust force, requires more feed force.

Advantages of Down Milling

- As opposed to up milling, down milling cut begins with a nonzero depth of cut (increases tool life)

- Welded chips break off

- Forces table down, creates less vibration.

- Feed drive power consumption lower

- Throws chips down instead of up

Milling Cutters

End Mill Geometry

- Flutes

- Flute length

- Cut length

- Rake angle

- Helix angle

- Relief angle

Machining Parameters

Speed

The distance the cutting edge of the cutter travels (fpm) each minute.

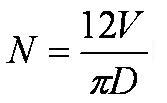

Convert Cutting Speed to rpm.

- V = cutting speed in fpm (Mach. Hndk).

- D = tool diameter in inches

- N = RPM

Feed Rate

Note! Spindle speed does not affect the feed rate.

fm = ft x nt x N

Where fm = Feed Rate in inches/min (not inches per revolution)

ft = Feed per tooth in inches

nt = Number of teeth on the cutter

N = Cutter rpm

Depth of Cut

- Axial

- Radial