Use Excel to create a worksheet that will program the CNC Mill to drill holes at user-entered X and Y coordinates.

See: Lecture for important details

See: How Canned Cycles Work with G98 & G99

Specifications

- The spreadsheet must be able to drill any number of holes up to ten maximum.

- All holes will be the same depth. User will enter depth for all holes.

- User will enter the following:

- Drill diameter

- Hole depth (positive value, cylindrical depth)

Tip angle(tip angle = 118°)

- Tool number

- Work origin (g54, G55, etc.)

- Feedrate

- Dwell

- Peck Depth

- Clamp height

- For each hole, user will enter:

- X location

- Y location

- Whether or not to jump after drilling.

- You will need to CALCULATE the z depth based on hole diameter and tip angle.

- Hint: The amount to add =(dia/2)/(TAN((RADIANS(angle/2))))

- Limit P and Q decimals to two.

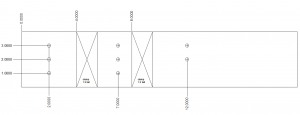

You will be given a drawing similar to the one below. You will be given the class period to enter the information and generate a program. Programs submitted after the end of class will be considered late.

%

(Begin Header)

G20 (Inch Mode)

G40 G17 G80 (comp cancel, plane, camp cancel)

T10 (Tool Number)

M06 (Tool Change)

G43 H10 (Length comp ON, Offset NO)

G55 (Part Zero Origin)

S1000 (Spindle Speed RPM)

M09 (Coolant Off)

G90 (Absolute)

M03

(End Header)

G00 Z1.7500

F10.0

G83 X2.0000 Y3.0000 Z-0.5751 R0.25 G99 P0.50 Q0.75 (Hole #1)

X2.0000 Y2.0000 Z-0.5751 G99 (Hole #2)

X2.0000 Y1.0000 Z-0.5751 G98 (Hole #3)

X7.0000 Y1.0000 Z-0.5751 G99 (Hole #4)

X7.0000 Y2.0000 Z-0.5751 G99 (Hole #5)

X7.0000 Y3.0000 Z-0.5751 G98 (Hole #6)

X12.0000 Y3.0000 Z-0.5751 G99 (Hole #7)

X12.0000 Y2.0000 Z-0.5751 G99 (Hole #8)

(Begin Footer)

G80 G00 Z6.0000

M30

%