Objectives

This project is designed to give students hands-on experience in product realization

- Provide experience in bringing a design concept to working drawings, process analysis, fixture design, and production.

- Develop sheet metal flat patterns for bent components using appropriate bend allowances.

- Develop sheet metal flat patterns of intersecting cones and cylinders.

- Design fixtures for bending operations, punching operations, and welding operations.

- Develop graphic, written and verbal skills by writing illustrated work instructions.

Assignment

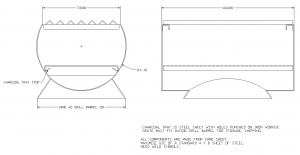

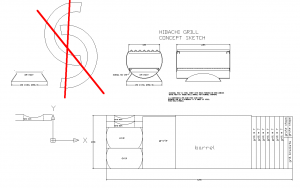

Below is a preliminary sketch of a small hibachi grill. Your job is to bring this product from concept to production. All components are to be made from a single sheet of 16 gauge steel sheet.

Deliverables

Packet 1 – A set of working drawings for each component and sub-assembly. Welded sub-assemblies should have proper weld notes. Drawings must conform to industry standards (ASME/ANSIN Y14.5M). All dimensions must have a tolerance. These should be turned in as a packet of drawings, stapled in the upper-left corner, cover sheet and letter of transmittal attached. Also in the packet should be a cutting pattern of all components nested on a single sheet. Components must be assigned a part number.

Paper/cardboard mockup. A full-scale cardboard mockup of the product is to be produced from your drawings in Packet 1.

Packet 2 – Working drawings for all fixtures. All operations must be made in fixtures of some kind. Production must be done without measuring or manual positioning. For simple clamp-on stops and similar fixturing, a partial work instruction will suffice.

Packet 3 – Illustrated work instructions for four operations. Work instruction should be written for untrained personnel. These include temporary employees, cross-training employees, and employees filling in for the regular operator.

Update 2-1-12:

The preliminary layout revealed that a small design change would yield a significant material savings as shown below:

Update 2-10-2012

Grill print has been revised, the AutoCAD file is available below.

Here are some of the significant changes to this version.

- All bends (except those for the feet) have been standardized to produce a .500 flange.

- Angle shapes have been standardized to .886 shear width.

- Grill hanger and grate hanger were not made identical. This permitted a significant material savings.

- Note: number of shearing ops can be reduced by 6 if all grill rails are sheared to length together.

2016 Hibachi Rev a (punch grate version)

Hibachi 2019A – Integrated Handle

Hibachi 2019B – Widened Slots

Hibachi 2019C – Widened slots even more

- Kerf width in 16 Gage steel is .035

CNC File for cutting slots in fixture (check tool number)

CNC File for engraving material placement (check tool number)