A progressive die set has been installed on the hydraulic press. You will use this press to make a single clip for your team. Measure the part and record your dimensions. Use the material thickness as the inside radius.

Each individual will do the following:

- Create a working drawing of the finished part (use CAD).

- Create a working drawing of the part in its unbent condition (a flat pattern). Show bends as hidden lines with a leader stating “BEND UP 90°.”

- Create a working drawing of the strip. Include a station that shows where the bends will take place.

- NOTE: Each working drawing (“print”) must be dimensioned properly. You may use the CAD software of your choice.

Using your drawings, answer the following questions:

- What is the volume of metal in the finished part?

- How much metal is thrown away for each part produced?

- What percentage of the material is used to produce a finished part?

- How much force is used to punch the material?

- How much force is used to bend the part (this is wipe bending)?

- If steel costs $3800 per ton, how much would it cost to produce 100,000 clips?

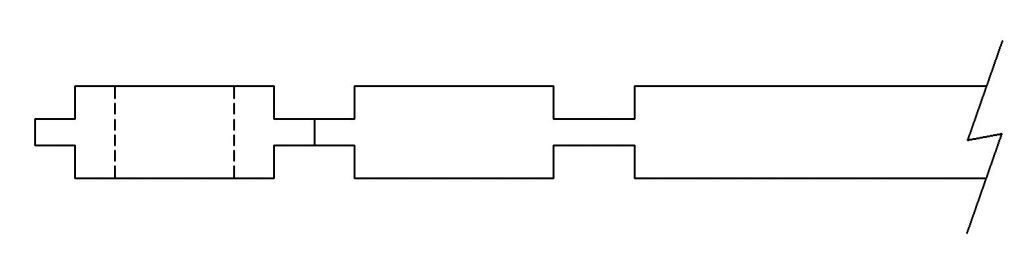

For reference, here is a working drawing of a die set assembly:

Cable Bracket Die (DWG)