Notes

Material

6061-T6511 aluminum flat bar 1.25 wide, .25 thick

Model

Working Drawings

Part

Fixture

Process Routing

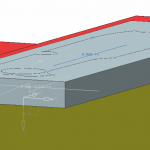

Position A

- Shear to length (CTS Ironworker)

- Assemble on “special parallel” (Haas TM1)

- Internal inside vise, machined side toward fixed jaw

- Slide to locating pin

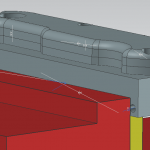

Position B

- Assemble on 003 FXT

- Standard Vise position

- Slide to locating pin

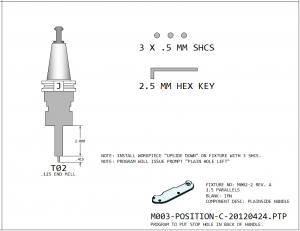

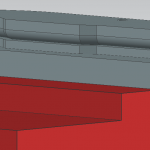

Position C

- Assemble UPSIDE DOWN on 002 FXT (Opposite side fixture)

- Standard Vise position

- Slide to locating pin

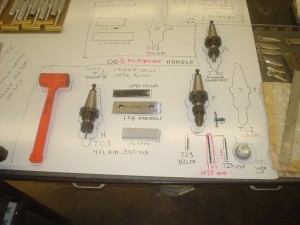

Draft 5S Layout

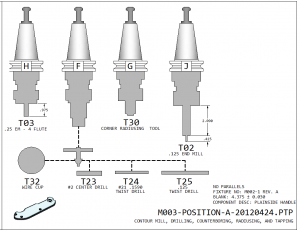

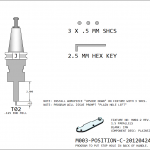

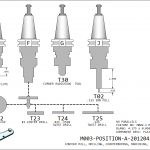

Tool Numbers (ref. only) Refer to master list for current details.

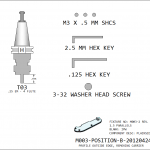

For Position A

- T03 (Holder H) 4fl end mill .250 diameter

- T23 (Holder F) #2 Center Drill

- T21 (Holder F) .1935 jobber twist drill

- T25 (Holder F) .125 jobber twist drill

- T02 (Holder J) .125 4fl end mill

- T30 (Holder G) Interstate corner radius tool

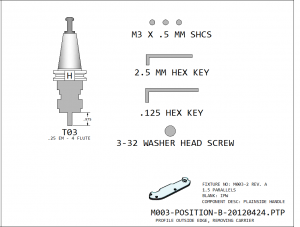

For Position B

- T03 (Holder H) 4fl end mill .250 diameter

For Position C

- T02 (Holder J) .125 4fl end mill

CAM Files

CNC Files

Setup 1

1.625 parallels, .090 Spacer

Setup 2

1.5 parallels, .003 fixture

Setup 3

Flip over onto 002 fixture

003_CNC_C1_drillStop – PLAIN HOLE LEFT