Notes

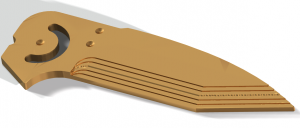

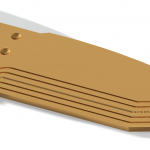

Material is currently 316 stainless, I would like to change it to A2 tool steel. Cost analysis needed. Advantages are heat treatability, better all-around knife steel. Disadvantage is additional cost, need for hear treatment. Need to talk to marketing. Current process is to machine this part. Look at making by other methods.

Note: Current models may not reflect the scalloped blade design. Need to change models to reflect this. Marketing wants the stepped blade.

Material

Currently using 316 Stainless (.125 thick)

Prototype material purchased from Speedy Metals

| 1 | $34.54 | $34.54 | 6f.125×1.5-72 | 1/8″ {A} x 1-1/2″ {B} 316 Stainless Steel |

Specifications

ASTM

- ASTM A276

- ASTM A479

- AMS 5648

Internal

Tractability issues

Optional Material (Tool Steel)

Model

Blade Rapid Prototype (STL) file

Working Drawings

Part

Fixture

Process Routing

- Shear bar to length (4.125)

- Machine

- M001-A

- M001-B

- M001-C

- Deburr

- Inspection

- Grind

- Polish

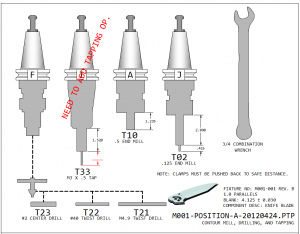

Machining Steps

AutoCAD File of 5s Layouts for all steps REV 20120424

Zip File of all CNC Programs, REV 20120424

CAM Files

- NX7 Manufacturing Files (zip) out of date

CNC Files

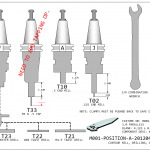

Setup 1, Position A

- 001_CNC_REV_B_A1_ProfileBlade

- 001_CNC_REV_B_A2_RestBlade

- 001_CNC_REV_B_A3_SpotBlade

- 001_CNC_REV_B_A4_m3TapDrillBlade

- 001_CNC_REV_B_A5_10-32ClearDrillBlade

- 001_ProductionPos_A

- Note: Need to add operation for tapping the thumb stud hole.

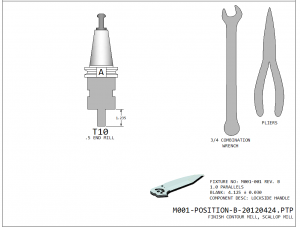

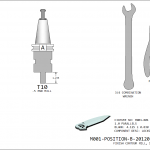

Setup 1, Position B

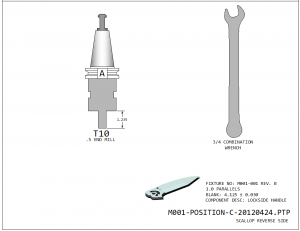

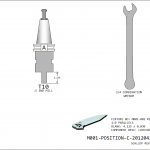

Setup 1, Position C

Photos