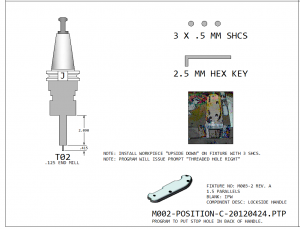

Notes

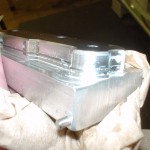

Material

6061-T6511

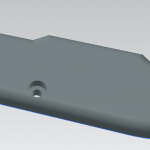

Model

Working Drawings

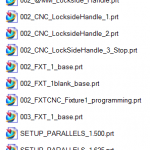

Part

Fixture

Process Routing

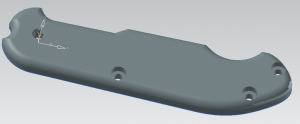

Position A

- Shear to length: 4.40 +/- .050 (CTS Ironworker)

- Assemble on “special parallel” (Haas TM1)

- Internal inside vise, machined side toward fixed jaw

Slide to locating pin

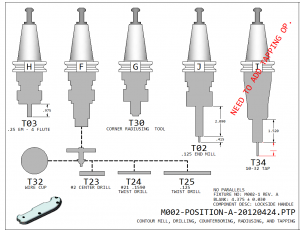

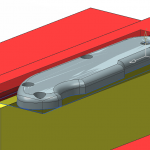

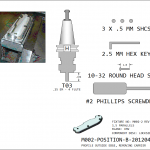

Position B

- Assemble on 002 FXT

- Standard Vise position

- Slide to locating pin

- Use 1.5 parallels

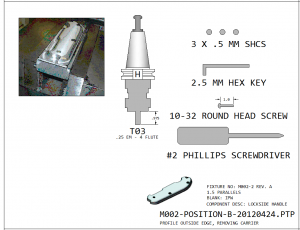

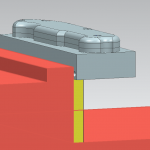

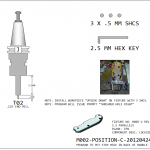

Position C

- Assemble UPSIDE DOWN on 003 FXT (Opposite side fixture)

- Standard Vise position

- Slide to locating pin

- Use 1.5 parallels

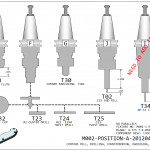

Tool Numbers (ref. only) Refer to master list for current details.

CAM Files

CNC Files

Setup 1 – 1.625 parallel, + 0.090 Spacer

002_CNC_1_LocksideHandle_1_profile

Setup 2 – 002 Fixture 1.500 parallel

002_CNC_8_LocksideHandle_2 (omit?)

Setup 3 – Flip over, assemble onto 003 fixture, use 1.500 parallels

002_CNC_LockSideHandle_3_Stop – THD HOLE RIGHT (mill hole for stop pin)