Linear move at a specified feed rate. It can cut in a single axis, or using multiple axes.

It is a modal command, so any coordinates that follow it will be treated as liner move destinations or distances (see G90/G91) until another command cancels it (such as a G00 or G02).

G1 is usually used to cut a straight line. Be sure you know about speeds, feeds and depth of cut before you select the cutting parameters.

The argument F sets the feedrate. The meaning is determined by the following commands (usually set in the header of the program).

- G93 – Time to complete the motion (Inverse time mode)

- G94 – Inches or mm per minute (IPM) (See G20/G21) <– The “usual” setting

- G95 -Inches or mm per spindle revolution (IPR)

If “F” is not present in the code block and has not been set by another feed command earlier in the program, most machines will throw an error. Also, for all arguments, including the F value, use a decimal point.

Once a G01 is started all programmed axes will move and reach the destination at the same time.

Example:

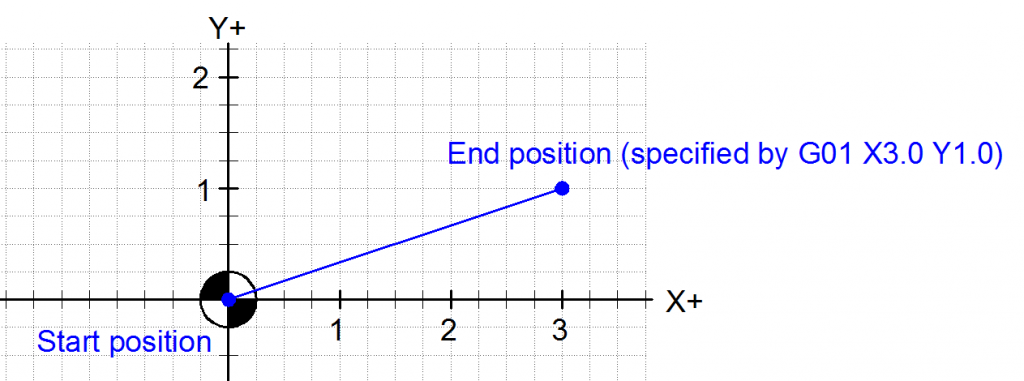

Assume G90, G20 and G94 have been set and the machine is currently at X0.0 Y0.0 Z0.0. For the following code:

G01 X3.0 Y1.0 F8.0;

The toolpath will look like this:

The cutting tool will move at 8 inches per minute.

See also Haas Manual

Pingback: CNC G Code: G02 and G03 - ManufacturingET.org