Rapid move to a point. (Not necessarily in a straight line!)

G0 (G zero) tells the machine to move as quickly as possible to a given point (absolute or relative, depending on the setting of G90 or 91). This command is modal, so any coordinates that follow will be rapid as well (until a Group 01 code is called). As with all G codes, it specifies only the destination point. HINT: It is usually a good idea to pull the Z up to a safe distance before executing a G0, since the path is not a straight line. Also, never rapid to or from a position too close to the workpiece. Leave some room for lead-ins and lead-outs. Be aware of the decimal point!

Takes the arguments (X, Y, Z, A, B).

Each of these is optional, A and B are for rotary axes. Notice there is no argument for feed rate, it is the machine max.

Example:

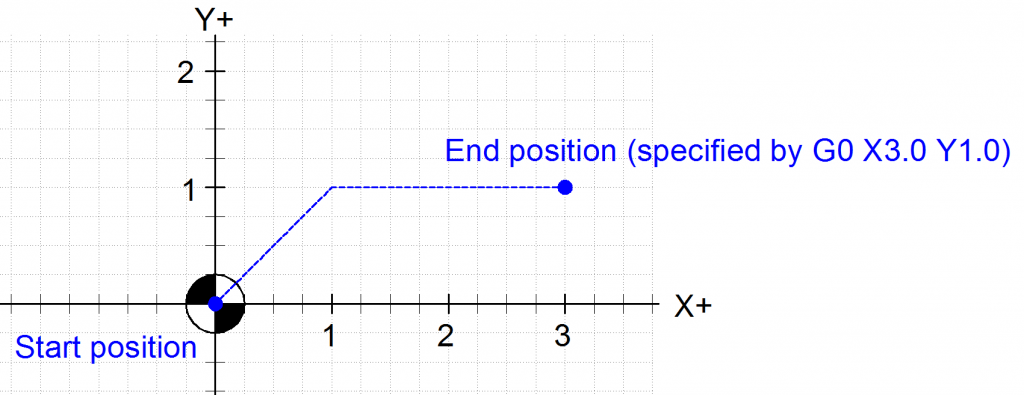

Assume the machine is currently at X0.0 Y0.0 and G90 is enabled. for the following code:

G0 X3.0 Y1.0 ;

The toolpath will look like this:

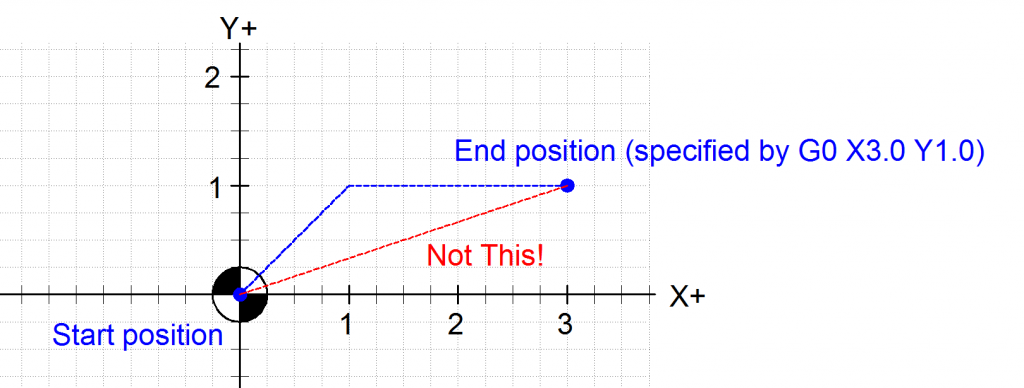

Don’t make the mistake of thinking the path looks like the one shown below in red! This is a crash waiting to happen.

The above example assumes milling, for turning, the only difference is the interpretation of the coordinate system.

See also: Haas Manual

Pingback: CNC G Code: G1 or G01 - ManufacturingET.org