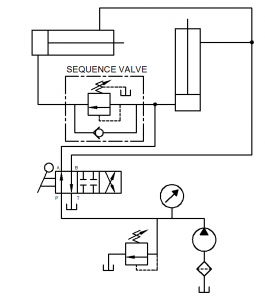

The application of a Sequencing Valve

Objective: To become more knowledgeable with the hydraulic system. A sequence valve is used to cause actions to take place in a system in a definite order, and maintain a predetermined minimum pressure in the primary line while the secondary operation occurs. See simulation here.

Sequencing valve Detail:

Procedure/demonstrations:

1. Make sure relief valve #2 is set at 500 Pound per square inch (PSI). Globe valve # 3 is open, Needle valve #4 is closed, and Needle vale #6 is open.

2. At manifold pressure gage #5 used the hoses connect to direction valve # 7.

3. Two-output gage at the direction valve # 7 use the hoses one connect to sequence valve # 8 and cylinder # 13, then another one connect to hydraulic cylinder # 12, and from the pipe tee at end cap of cylinder # 12 use the hoses connect to cylinder # 13 as show above.

4. Make sure direction valve # 7 is in center or neutral position.

5. Increase pressure setting of sequence valve # 8 as far as possible.

6. Turn on power unit.

7. Shift direction valve # 7 to extend piston rod of # 12 and # 13.

8. We will see that only piston rod #13 extension and system pressure then increases to relief valve setting.

9. Reduce pressure setting of sequence valve # 8 until piston # 13 extends and gage #15 read at least 150 PSI less than relief valve setting. Extends and retract piston rod # 12 and # 13 a few time, so that the sequence valve operation and the different pressure indicated on gage #15.

10. Turn off power unit.

Discussion:

In this case, the sequence valve is used to cause action to take place in a system in a definite order, and to maintain a predetermined minimum pressure in the primary line while the secondary operation. The fluid flows freely through the primary passage to operate the first phase until the pressure setting of the valve is reached. As the spool lifts, flow is diverted to the secondary port to operate a second phase.

Conclusion:

The sequence valve is suitable for system where it can be installed upstream from the direction valve. If it is installed downstream a cylinder line, some provision must be made for return free flow when the cylinder is reversed. A typical application in this case it is clamping from the primary port and feeling a drill head from the secondary after the work piece is firmly clamped.