Objective: To become more knowledgeable with the hydraulic system. The actuator is the general term used for the output device of hydraulic system. Two broad categories are linear actuators that deliver power in a straight line, and rotary actuator that deliver their power in a rotating or circular motion. The linear device is called a hydraulic cylinder. Hydraulic cylinder is linear actuator. This means that the output of a cylinder is a straight-line motion or force. The major function of a hydraulic is to convert hydraulic power into linear mechanical force to perform work or transmit power.

Procedure/ demonstrations:

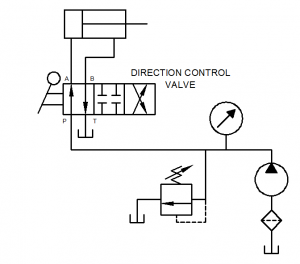

1. Make sure relief valve #2 is set at 500 Pound per square inch (PSI). Globe valve # 3 is open, Needle valve #4 is closed, and Needle vale #6 is open.

2. At manifold pressure gauge #5 used the hoses connect with direction valve # 7.

3. Two-output gauge on the direction valve # 7 use the hoses connect with cylinder #12.

4. Shift direction valve # 7 to center or neutral position.

5. Turn on hydraulic power supply.

6. Shift direction valve # 7 to extend and retract both piston rod. We will see cylinder pressure to extend and retract.

7. Turn off hydraulic power supply.

Now: Re-design the circuit to apply an equal pressure to the rod and cap end of the cylinder. What is the predicted result? What is the actual result?

Discussion:

When we turn power on then shift direction valve to extend and retract we will see the cylinder pressure to extend and retract. This is a double acting cylinder is the most common type used in industrial hydraulics. Hydraulic pressure is applied to either port, providing powered motion when extending or retracting. The majority of cylinder in use is basic double acting cylinder as above. That cylinder is classed as differential cylinder because there is unequal area exposed to pressure during the extend and retract movements. The difference is cause by the cross section area of the rod, which reduces the area under pressure during retraction. Rod extension velocity is slower than retraction because more fluid is required to fill the swept volume of the piston. However, greater force is possible because the pressure operates in the full piston area. When retracting, the same flow from a pump causes faster movement of the cylinder because the volume of the cylinder rod reduces the swept volume. With the same system pressure, the maximum force exerted by the cylinder is also less because of the smaller area under pressure. Cylinder speed, the output force available, and the pressure required for a given load are all dependent on the piston area when extending the rod. When retracting the rod, the affective area of the rod end of the cylinder must be used. This “affective area” or “annulus area,” of the rod end is determined by subtracting the area of the rod from the piston area.

Summary: Hydraulic cylinder is among the simplest of devices in fluid power, having one moving part: the piston and the rod assembly. However, forces generated by cylinders are also among the largest found in fluid power systems. Pressure in the cylinders can, and often do, exceed system relief settings. The life of the cylinder and the system can be highly dependent on proper specification and maintenance of a simple element, the rod wiper/scraper.