The Unified Thread Standard (UTS) defines a standard thread form and series—along with allowances, tolerances, and designations—for screw threads commonly used in the United States and Canada. It has the same 60° profile as the ISO metric screw thread used in the rest of the world, but the characteristic dimensions of each UTS thread (outer diameter and pitch) were chosen as an inch fraction rather than a round millimeter value. The UTS is currently controlled by ASME/ANSI in the United States.

Contents |

Origins

Basic profile

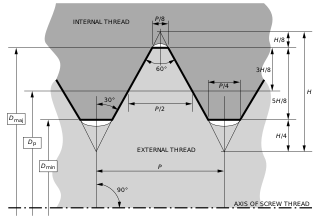

The basic profile of all UTS threads is the same as that of all ISO metric screw threads. Only the commonly used values for Dmaj and P differ between the two standards.

Each thread in the series is characterized by its major diameter Dmaj and its pitch, P. UTS threads consist of a symmetric V-shaped thread. In the plane of the thread axis, the flanks of the V have an angle of 60° to each other. The outermost 0.125 and the innermost 0.25 of the height H of the V-shape are cut off from the profile.

The pitch P is the distance between thread peaks. For UTS threads, which are single-start threads, it is equal to the lead, the axial distance that the screw advances during a 360° rotation. UTS threads do not usually use the pitch parameter; instead a parameter known as threads per inch (TPI) is used, which is the reciprocal of the pitch.

The relationship between the height H and the pitch P is found using the following equation:[1]

In an external (male) thread (e.g., on a bolt), the major diameter Dmaj and the minor diameter Dmin define maximum dimensions of the thread. This means that the external thread must end flat at Dmaj, but can be rounded out below the minor diameter Dmin. Conversely, in an internal (female) thread (e.g., in a nut), the major and minor diameters are minimum dimensions, therefore the thread profile must end flat at Dmin but may be rounded out beyond Dmaj.

The minor diameter Dmin and effective pitch diameter Dp are derived from the major diameter and pitch as

Designation

The standard designation for a UTS thread is a number indicating the nominal (major) diameter of the thread, followed by the pitch measured in threads per inch. For diameters smaller than ¼ inch, the diameter is indicated by an integer number defined in the standard, for all other diameters, the inch figure is given.

This number pair is optionally followed by the letters UNC, UNF or UNEF if the diameter-pitch combination is from the “coarse”, “fine” or “extra fine” series, and may also be followed by a tolerance class.

Example: 6-32 UNC 2B (major diameter: 0.1380 inch, pitch: 32 tpi)

| Major diameter[in (mm)] | Threads per inch | Tap drill size | ||||

|---|---|---|---|---|---|---|

| Coarse (UNC) | Fine (UNF) | Extra fine (UNEF) | Coarse | Fine | Extra fine | |

| #0 = 0.0600 (1.5240) | – | 80 | 3/64 in | |||

| #1 = 0.0730 (1.8542) | 64 | 72 | #53 | #53 | ||

| #2 = 0.0860 (2.1844) | 56 | 64 | #50 | #50 | ||

| #3 = 0.0990 (2.5146) | 48 | 56 | #47 | #45 | ||

| #4 = 0.1120 (2.8448) | 40 | 48 | #43 | #42 | ||

| #5 = 0.1250 (3.1750) | 40 | 44 | #38 | #37 | ||

| #6 = 0.1380 (3.5052) | 32 | 40 | #36 | #33 | ||

| #8 = 0.1640 (4.1656) | 32 | 36 | #29 | #29 | ||

| #10 = 0.1900 (4.8260) | 24 | 32 | #25 | #21 | ||

| #12 = 0.2160 (5.4864) | 24 | 28 | 32 | #16 | #14 | |

| 1⁄4 (6.3500) | 20 | 28 | 32 | #7 | #3 | |

| 5⁄16 (7.9375) | 18 | 24 | 32 | F | I | |

| 3⁄8 (9.5250) | 16 | 24 | 32 | 5/16 in | Q | |

| 7⁄16 (11.1125) | 14 | 20 | 28 | U | 25/64 in | |

| 1⁄2 (12.7000) | 13 | 20 | 28 | 27/64 in | 29/64 in | |

| 9⁄16 (14.2875) | 12 | 18 | 24 | 31/64 in | 33/64 in | |

| 5⁄8 (15.8750) | 11 | 18 | 24 | 17/32 in | 37/64 in | |

| 3⁄4 (19.0500) | 10 | 16 | 20 | 21/32 in | 11/16 in | |

| 7⁄8 (22.2250) | 9 | 14 | 20 | 49/64 in | 13/16 in | |

| 1 (25.4000) | 8 | 14* | 20 | 7/8 in | 59/64 in | |

*1-12 was formerly a widespread standard, but 1-14 is current UNF.[citation needed]

The following formula is used to calculate the major diameter of a numbered screw greater than or equal to 0: Major diameter = Screw # × 0.013″ + 0.060″. For example, a number 10 calculates as: #10 × 0.013″ + 0.060″ = 0.190″ major diameter.

A Unified Miniature screw thread series is defined in ANSI standard B1.10, for fasteners of 0.3 to 1.4 millimetres (0.0118 to 0.0551 inch) diameter. These sizes are intended for watches, instruments, and miniature mechanisms and are interchangeable with threads made to ISO Standard 68.[3] These screw sizes are denoted by multiple zeroes, i.e. #000. The formula for number sizes smaller than size #0 is given by Major diameter = 0.060″ – Zero size × 0.013″, with the zero size being the number of zeroes after the first. So a #00 screw is .047″ dia, #000 is .034″ dia, etc.[citation needed]

The number series of machine screws once included more odd numbers and went up to #16 or more. Standardization efforts in the late 19th and the early part of the 20th century reduced the range of sizes considerably. Now, it is less common to see machine screws larger than #14, or odd number sizes other than #1, #3 and #5. Even though #14 and #16 screws are still available, they are not as common as sizes #0 through #12.[citation needed]

Sometimes “special” diameter and pitch combinations (UNS) are used, for example a 0.619 in (15.7 mm) major diameter with 20 threads per inch. UNS threads are rarely used for bolts, but rather on nuts, tapped holes, and threaded OD’s. Because of this UNS taps are readily available.[4][5] Most UNS threads have more threads per inch than the correlating UNF or UNEF standard, therefore they are often the strongest thread available.[6] Because of this they are often used in applications where high stresses are encountered, such as machine tool spindles[7] or automotive spindles.[8]

Gaging

A screw thread gaging system comprises a list of screw thread characteristics that must be inspected to establish the dimensional acceptability of the screw threads on a threaded product and the gage(s) which shall be used when inspecting those characteristics.

Currently this gaging UTS is controlled by:

- ASME/ANSI B1.2-1983 Gages And Gaging For Unified Inch Screw Threads

- ASME/ANSI B1.3M-1992 Screw Thread Gaging Systems Dimensional Acceptability Inch Metric Screw Threads

These standards provide essential specifications and dimensions for the gages used on Unified inch screw threads (UN, UNR, UNJ thread form) on externally and internally threaded products. It also covers the specifications and dimensions for the thread gages and measuring equipment. The basic purpose and use of each gage are also described. It also establishes the criteria for screw thread acceptance when a gaging system is used.

Tolerance classes

A classification system exists for ease of manufacture and interchangeability of fabricated threaded items. Most (but certainly not all) threaded items are made to a classification standard called the Unified Screw Thread Standard Series. This system is analogous to the fits used with assembled parts.

Classes 1A, 2A, 3A apply to external threads; Classes 1B, 2B, 3B apply to internal threads.

Class 1 threads are loosely fitting threads intended for ease of assembly or use in a dirty environment.

Class 2 threads are the most common. They are designed to maximize strength considering typical machine shop capability and machine practice.

Class 3 threads are used for closer tolerances.

Thread class refers to the acceptable range of pitch diameter for any given thread. The pitch diameter is indicated as Dp in the figure shown above. There are several methods that are used to measure the pitch diameter. The most common method used in production is by way of a Go/no go gauge.

Related standards

- ASME/ANSI B1.1 – 2003 Unified Inch Screw Threads, UN & UNR Thread Form

- ASME/ANSI B1.10M – 2004 Unified Miniature Screw Threads

- ASME/ANSI B1.15 – 1995 Unified Inch Screw Threads, UNJ Thread Form

See also

Notes

- ^ Oberg et al. 2000, p. 1706.

- ^ For a metric conversion see the drill bit sizes article.

- ^ Ryffel 1988, p. 1547.

- ^ McMaster-Carr p. 2520, http://www.mcmaster.com/#catalog/115/2520/=3dxzrr, retrieved 2009-08-28.

- ^ McMaster-Carr p. 2501, http://www.mcmaster.com/#catalog/115/2501/=3dy2xw, retrieved 2009-08-28.

- ^ Schwaller 2004, p. 55.

- ^ Special connections, http://www.nuraseal.com/Filton/Special_Connections/Special_Connections.htm, retrieved 2009-08-28.

- ^ Hub components, http://i.b5z.net/i/u/1080235/f/parts_kit_cat_8-08/Hub_Components.pdf, retrieved 2009-08-29.

Bibliography

- Ryffel, Henry H., et al. (eds) (1988), Machinery’s Handbook (23rd ed.), New York: Industrial Press, ISBN 978-0-8311-1200-4.

- Schwaller, Anthony E. (2004), Total Automotive Technology (4th ed.), Cengage Learning, ISBN 9781401824761, http://books.google.com/?id=tpzOoC_G4HAC.

External links

- Unified Coarse standard and drill sizes

- Unified Fine standard and drill sizes

- Unified Coarse/Fine diameters and tap drill sizes (US units)

- Unified Coarse/Fine tap drill sizes (US units)

- Imperial Metric fastening size conversion charts

- International Thread Standards

- Conversion chart Whitworth/BSF/AF and metric

- Spanner Jaw Sizes Additional information and spanner jaw size table.

- Unified Screw Threads Series

This information originally retrieved from http://en.wikipedia.org/wiki/Unified_Thread_Standard

on Wednesday 19th October 2011 7:21 pm EDT

Now edited and maintained by ManufacturingET.org