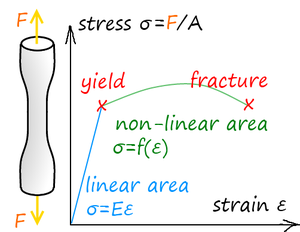

Stress-strain relations

- Elasticity is the ability of a material to return to its previous shape after stress is released. In many materials, the relation between applied stress and the resulting strain is directly proportional (up to a certain limit), and a graph representing those two quantities is a straight line.

The slope of this line is known as Young’s Modulus, or the “Modulus of Elasticity.” The Modulus of Elasticity can be used to determine stress-strain relationships in the linear-elastic portion of the stress-strain curve. The linear-elastic region is either below the yield point, or if a yield point is not well defined for the material, taken to be between 0 and 0.2% strain, and is defined as the region of strain in which no yielding (permanent deformation) occurs.[11]

- Plasticity or plastic deformation is the opposite of elastic deformation and is accepted as unrecoverable strain. Plastic deformation is retained even after the relaxation of the applied stress. Most materials in the linear-elastic category are usually capable of plastic deformation. Brittle materials, like ceramics, do not experience any plastic deformation and will fracture under relatively low stress. Materials such as metals usually experience a small amount of plastic deformation before failure while ductile metals such as copper and lead or polymers will plasticly deform much more.

Consider the difference between a carrot and chewed bubble gum. The carrot will stretch very little before breaking, but nevertheless will still stretch. The chewed bubble gum, on the other hand, will plastically deform enormously before finally breaking.

^ Beer & Johnston (2006). Mechanics of Materials (5th ed.). McGraw Hill. pp. 53–56. ISBN 978-0-07-352938-7.

Source: Adapted from http://en.wikipedia.org/wiki/Strength_of_materials