Aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances. Aluminium is the most abundant metal in the Earth‘s crust, and the third most abundant element, after oxygen and silicon. It makes up about 8% by weight of the Earth’s solid surface. Aluminium metal is too reactive chemically to occur in nature. Instead, it is found combined in over 270 different minerals.[5] The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal’s low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, aluminium salts are not known to be used by any form of life. In keeping with its pervasiveness, it is well tolerated by plants and animals.[6] Because of its prevalence, potential biological roles, beneficial and otherwise, for aluminium compounds are of continuing interest.

Contents |

Characteristics

Physical

Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. Aluminium is nonmagnetic and nonsparking.[clarification needed] It is also insoluble in alcohol, though it can be soluble in water in certain forms. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[7] Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Corrosion resistance can be excellent due to a thin surface layer of aluminium oxide that forms when the metal is exposed to air, effectively preventing further oxidation. The strongest aluminium alloys are less corrosion resistant due to galvanic reactions with alloyed copper.[7] This corrosion resistance is also often greatly reduced when many aqueous salts are present, particularly in the presence of dissimilar metals.

Aluminium atoms are arranged in a face-centered cubic (fcc) structure. Aluminium has a stacking-fault energy of approximately 200 mJ/m2.[8]

Aluminium is one of the few metals that retain full silvery reflectance in finely powdered form, making it an important component of silver-colored paints. Aluminium mirror finish has the highest reflectance of any metal in the 200–400 nm (UV) and the 3,000–10,000 nm (far IR) regions; in the 400–700 nm visible range it is slightly outperformed by tin and silver and in the 700–3000 (near IR) by silver, gold, and copper.[9]

Aluminium is a good thermal and electrical conductor, having 59% the conductivity of copper, both thermal and electrical. Aluminium is capable of being a superconductor, with a superconducting critical temperature of 1.2 Kelvin and a critical magnetic field of about 100 gauss (10 milliteslas).[10]

Creation

Stable aluminium is created when hydrogen fuses with magnesium either in large stars or in supernovae.[11]

Isotopes

Aluminium has many known isotopes, whose mass numbers range from 21 to 42; however, only 27Al (stable isotope) and 26Al (radioactive isotope, t1/2 = 7.2×105 y) occur naturally. 27Al has a natural abundance above 99.9%. 26Al is produced from argon in the atmosphere by spallation caused by cosmic-ray protons. Aluminium isotopes have found practical application in dating marine sediments, manganese nodules, glacial ice, quartz in rock exposures, and meteorites. The ratio of 26Al to 10Be has been used to study the role of transport, deposition, sediment storage, burial times, and erosion on 105 to 106 year time scales.[12] Cosmogenic 26Al was first applied in studies of the Moon and meteorites. Meteoroid fragments, after departure from their parent bodies, are exposed to intense cosmic-ray bombardment during their travel through space, causing substantial 26Al production. After falling to Earth, atmospheric shielding drastically reduces 26Al production, and its decay can then be used to determine the meteorite’s terrestrial age. Meteorite research has also shown that 26Al was relatively abundant at the time of formation of our planetary system. Most meteorite scientists believe that the energy released by the decay of 26Al was responsible for the melting and differentiation of some asteroids after their formation 4.55 billion years ago.[13]

Natural occurrence

In the Earth’s crust, aluminium is the most abundant (8.3% by weight) metallic element and the third most abundant of all elements (after oxygen and silicon).[14] Because of its strong affinity to oxygen, it is almost never found in the elemental state; instead it is found in oxides or silicates. Feldspars, the most common group of minerals in the Earth’s crust, are aluminosilicates. Native aluminium metal can be found as a minor phase in low oxygen fugacity environments, such as the interiors of certain volcanoes.[15] Native aluminium has been reported in cold seeps in the northeastern continental slope of the South China Sea and Chen et al. (2011)[16] have proposed a theory of its origin as resulting by reduction from tetrahydroxoaluminate Al(OH)4– to metallic aluminium by bacteria.[16]

It also occurs in the minerals beryl, cryolite, garnet, spinel and turquoise. Impurities in Al2O3, such as chromium or iron yield the gemstones ruby and sapphire, respectively.

Although aluminium is an extremely common and widespread element, the common aluminium minerals are not economic sources of the metal. Almost all metallic aluminium is produced from the ore bauxite (AlOx(OH)3-2x). Bauxite occurs as a weathering product of low iron and silica bedrock in tropical climatic conditions.[17] Large deposits of bauxite occur in Australia, Brazil, Guinea and Jamaica and the primary mining areas for the ore are in Australia, Brazil, China, India, Guinea, Indonesia, Jamaica, Russia and Surinam.

Production and refinement

Although aluminium is the most abundant metallic element in the Earth’s crust, it is never found in free, metallic form.

Aluminium forms strong chemical bonds with oxygen. Compared to most other metals, it is difficult to extract from ore, such as bauxite, due to the energy required to reduce aluminium oxide (Al2O3). For example, direct reduction with carbon, as is used to produce iron, is not chemically possible, since aluminium is a stronger reducing agent than carbon. There is an indirect carbothermic reduction possible by using carbon and Al2O3, which forms an intermediate Al4C3 and this can further yield aluminium metal at a temperature of 1900–2000°C. This process is still under development. This process costs less energy and yields less CO2 than the Hall-Héroult process, the major industrial process for aluminium extraction.[18] Aluminium oxide has a melting point of about 2,000 °C (3,600 °F). Therefore, it must be extracted by electrolysis. In this process, the aluminium oxide is dissolved in molten cryolite with calcium fluoride and then reduced to the pure metal. The operational temperature of the reduction cells is around 950 to 980 °C (1,740 to 1,800 °F). Cryolite is found as a mineral in Greenland, but in industrial use it has been replaced by a synthetic substance. Cryolite is a chemical compound of aluminium and sodium fluorides: (Na3AlF6). The aluminium oxide (a white powder) is obtained by refining bauxite in the Bayer process of Karl Bayer. (Previously, the Deville process was the predominant refining technology.)

The electrolytic process replaced the Wöhler process, which involved the reduction of anhydrous aluminium chloride with potassium. Both of the electrodes used in the electrolysis of aluminium oxide are carbon. Once the refined alumina is dissolved in the electrolyte, its ions are free to move around. The reaction at the cathode is:

- Al3+ + 3 e− → Al

Here the aluminium ion is being reduced. The aluminium metal then sinks to the bottom and is tapped off, usually cast into large blocks called aluminium billets for further processing.

At the anode, oxygen is formed:

- 2 O2− → O2 + 4 e−

To some extent, the carbon anode is degraded by the oxygen. The anodes in a reduction cell must therefore be replaced regularly, since they are consumed in the process. The cathodes do erode, mainly due to electrochemical processes and metal movement. After five to ten years, depending on the current used in the electrolysis, a cell has to be rebuilt because of cathode wear.

Aluminium electrolysis with the Hall-Héroult process consumes a lot of energy, but alternative processes were always found to be less viable economically and/or ecologically. The worldwide average specific energy consumption is approximately 15±0.5 kilowatt-hours per kilogram of aluminium produced (52 to 56 MJ/kg). The most modern smelters achieve approximately 12.8 kW·h/kg (46.1 MJ/kg). (Compare this to the heat of reaction, 31 MJ/kg, and the Gibbs free energy of reaction, 29 MJ/kg.) Reduction line currents for older technologies are typically 100 to 200 kiloamperes; state-of-the-art smelters operate at about 350 kA. Trials have been reported with 500 kA cells.

The Hall-Heroult process produces aluminium with a purity of above 99%. Further purification can be done by the Hoope process. The process involves the electrolysis of molten aluminium with a sodium, barium and aluminium fluoride electrolyte. The resulting aluminium has a purity of 99.99%.[19][20]

Electric power represents about 20% to 40% of the cost of producing aluminium, depending on the location of the smelter. Aluminum production consumes roughly 5% of electricity generated in the U.S.[21] Smelters tend to be situated where electric power is both plentiful and inexpensive, such as the United Arab Emirates with excess natural gas supplies and Iceland and Norway with energy generated from renewable sources. The world’s largest smelters of alumina are People’s Republic of China, Russia, and Quebec and British Columbia in Canada.[22][23][21]

In 2005, the People’s Republic of China was the top producer of aluminium with almost a one-fifth world share, followed by Russia, Canada, and the USA, reports the British Geological Survey.

Over the last 50 years, Australia has become a major producer of bauxite ore and a major producer and exporter of alumina (before being overtaken by China in 2007).[22][24] Australia produced 62 million tonnes of bauxite in 2005. The Australian deposits have some refining problems, some being high in silica, but have the advantage of being shallow and relatively easy to mine.[25]

Recycling

Aluminium recycling code

Aluminium is 100% recyclable without any loss of its natural qualities. Recovery of the metal via recycling has become an important facet of the aluminium industry. Recycling was a low-profile activity until the late 1960s, when the growing use of aluminium beverage cans brought it to the public awareness.

Recycling involves melting the scrap, a process that requires only 5% of the energy used to produce aluminium from ore, though a significant part (up to 15% of the input material) is lost as dross (ash-like oxide).[26] The dross can undergo a further process to extract aluminium.

In Europe aluminium experiences high rates of recycling, ranging from 42% of beverage cans, 85% of construction materials and 95% of transport vehicles.[27]

Recycled aluminium is known as secondary aluminium, but maintains the same physical properties as primary aluminium. Secondary aluminium is produced in a wide range of formats and is employed in 80% of the alloy injections. Another important use is for extrusion.

White dross from primary aluminium production and from secondary recycling operations still contains useful quantities of aluminium that can be extracted industrially.[28] The process produces aluminium billets, together with a highly complex waste material. This waste is difficult to manage. It reacts with water, releasing a mixture of gases (including, among others, hydrogen, acetylene, and ammonia), which spontaneously ignites on contact with air;[29] contact with damp air results in the release of copious quantities of ammonia gas. Despite these difficulties, the waste has found use as a filler in asphalt and concrete.[30]

Compounds

Oxidation state +3

The vast majority of compounds, including all Al-containing minerals and all commercially significant aluminium compounds, feature aluminium in the oxidation state 3+. The coordination number of such compounds varies, but generally Al3+ is six-coordinate or tetracoordinate. Almost all compounds of aluminium(III) are colorless.[14]

Halides

All four trihalides are well known. Unlike the structures of the three heavier trihalides, aluminium fluoride (AlF3) features six-coordinate Al. The octahedral coordination environment for AlF3 is related to the compactness of fluoride ion, six of which can fit around the small Al3+ centre. AlF3 sublimes (with cracking) at 1,291 °C (2,356 °F). With heavier halides, the coordination numbers are lower. The other trihalides are dimeric or polymeric with tetrahedral Al centers. These materials are prepared by treating aluminium metal with the halogen, although other methods exist. Acidification of the oxides or hydroxides affords hydrates. In aqueous solution, the halides often form mixtures, generally containing six-coordinate Al centres, which are feature both halide and aquo ligands. When aluminium and fluoride are together in aqueous solution, they readily form complex ions such as [AlF(H2O)5]2+, AlF3(H2O)3, and [AlF6]3−. In the case of chloride, polyaluminium clusters are formed such as [Al13O4(OH)24(H2O)12]7+.

Oxide and hydroxides

Aluminium forms one stable oxide, known by its mineral name corundum. Sapphire and ruby are impure corundum contaminated with trace amounts of other metals. The two oxide-hydroxides (AlO(OH) are boehmite and diaspore. There are three trihydroxides: bayerite, gibbsite, and nordstrandite, which differ in their crystalline structure (polymorphs). Most are produced from ores by a variety of wet processes using acid and base. Heating the hydroxides leads to formation of corundrum. These materials are of central importance to the production of aluminium and are themselves extremely useful.

Aluminium carbide (Al4C3) is made by heating a mixture of the elements above 1,000 °C (1,832 °F). The pale yellow crystals consist of tetrahedral aluminium centres. It reacts with water or dilute acids to give methane. The acetylide, Al2(C2)3, is made by passing acetylene over heated aluminium.

Aluminium nitride (AlN) is the only nitride known for aluminium. Unlike the oxides it features tetrahedral Al centres. It can be made from the elements at 800 °C (1,472 °F). It is air-stable material with a usefully high thermal conductivity. Aluminium phosphide (AlP) is made similarly, and hydrolyses to give phosphine:

- AlP + 3 H2O → Al(OH)3 + PH3

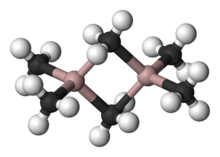

Structure of trimethylaluminium, a compound that features five-coordinate carbon.

A variety of compounds of empirical formula AlR3 and AlR1.5Cl1.5 exist.[31] These species usually feature tetrahedral Al centres, e.g. “trimethylaluminium” has the formula Al2(CH3)6 (see figure). With large organic groups, triorganoaluminium exist as three-coordinate monomers, such as triisobutylaluminium. Such compounds are widely used in industrial chemistry, despite the fact that they are often highly pyrophoric. Few analogues exist between organoaluminium and organoboron compounds except for large organic groups.

The important aluminium hydride is lithium aluminium hydride (LiAlH4), which is used in as a reducing agent in organic chemistry. It can be produced from lithium hydride and aluminium trichloride:

- 4 LiH + AlCl3 → LiAlH4 + 3 LiCl

Several useful derivatives of LiAlH4 are known, e.g. Sodium bis(2-methoxyethoxy)dihydridoaluminate. The simplest hydride, aluminium hydride or alane, remains a laboratory curiosity. It is a polymer with the formula (AlH3)n, in contrast to the corresponding boron hydride with the formula (BH3)2.

Oxidation states +1 and 2+

Although the great majority of aluminium compounds feature Al3+ centres, compounds with lower oxidation states are known and sometime of significance as precursors to the Al3+ species.

Aluminium(I)

AlF, AlCl and AlBr exist in the gaseous phase when the tri-halide is heated with aluminium. The composition AlI is unstable at room temperature with respect to the triiodide:[32]

- 3 AlI → AlI3 + 2 Al

A stable derivative of aluminium monoiodide is the cyclic adduct formed with triethylamine, Al4I4(NEt3)4. Also of theoretical interest but only of fleeting existence are Al2O and Al2S is made by heating the normal oxide, Al2O3, with silicon at 1,800 °C (3,272 °F) in a vacuum.[32] Such materials quickly disproportionates to the starting materials.

Aluminium(II)

Very simple Al(II) compounds are invoked or observed in the reactions of Al metal with oxidants. For example, aluminium monoxide, AlO, has been detected in the gas phase after explosion[33] and in stellar absorption spectra.[34] More thoroughly investigated are compounds of the formula R4Al2 where R is a large organic ligand.[35]

Analysis

The presence of aluminium can be detected in qualitative analysis using aluminon.

Applications

General use

Aluminium is the most widely used non-ferrous metal.[36] Global production of aluminium in 2005 was 31.9 million tonnes. It exceeded that of any other metal except iron (837.5 million tonnes).[37] Forecast for 2012 is 42–45 million tons, driven by rising Chinese output.[38] Relatively pure aluminium is encountered only when corrosion resistance and/or workability is more important than strength or hardness. A thin layer of aluminium can be deposited onto a flat surface by physical vapour deposition or (very infrequently) chemical vapour deposition or other chemical means to form optical coatings and mirrors. When so deposited, a fresh, pure aluminium film serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation.

Pure aluminium has a low tensile strength, but when combined with thermo-mechanical processing, aluminium alloys display a marked improvement in mechanical properties, especially when tempered. Aluminium alloys form vital components of aircraft and rockets as a result of their high strength-to-weight ratio. Aluminium readily forms alloys with many elements such as copper, zinc, magnesium, manganese, and silicon (e.g., duralumin). Today, almost all bulk metal materials that are referred to loosely as “aluminium”, are actually alloys. For example, the common aluminium foils and beverage cans are alloys of 92% to 99% aluminium.[39]

Household aluminium foil

Aluminium-bodied Austin “A40 Sports” (circa 1951)

Some of the many uses for aluminium metal are in:

- Transportation (automobiles, aircraft, trucks, railway cars, marine vessels, bicycles, etc.) as sheet, tube, castings, etc.

- Packaging (cans, foil, etc.)

- Construction (windows, doors, siding, building wire, etc.)

- A wide range of household items, from cooking utensils to baseball bats, watches.[40]

- Street lighting poles, sailing ship masts, walking poles, etc.

- Outer shells of consumer electronics, also cases for equipment e.g. photographic equipment.

- Electrical transmission lines for power distribution

- MKM steel and Alnico magnets

- Super purity aluminium (SPA, 99.980% to 99.999% Al), used in electronics and CDs.

- Heat sinks for electronic appliances such as transistors and CPUs.

- Substrate material of metal-core copper clad laminates used in high brightness LED lighting.

- Powdered aluminium is used in paint, and in pyrotechnics such as solid rocket fuels and thermite.

- Aluminium can be reacted with hydrochloric acid or with sodium hydroxide to prodce hydrogen gas.

- A variety of countries, including France, Italy, Poland, Finland, Romania, Israel, and the former Yugoslavia, have issued coins struck in aluminium or aluminium-copper alloys.[41]

- Some guitar models sports aluminium diamond plates on the surface of the instruments, usually either chrome or black. Kramer Guitars and Travis Bean are both known for having produced guitars with necks made of aluminium, which gives the instrument a very distinct sound.

- Sustainability of Aluminium in Buildings

Aluminium compounds

Because aluminium is abundant and most of its compounds exhibit low toxicity, the compounds of aluminium enjoy wide and sometimes large-scale applications.

Alumina

Aluminium oxide (Al2O3) and the associated oxy-hydroxides and trihydroxides are produced or extracted from minerals on a large scale. The great majority of this material is converted to metallic aluminium. About 10% of the production capacity is used for other applications. A major use is as an absorbent, for example alumina will remove water from hydrocarbons, to enable subsequent processes that are poisoned by moisture. Aluminum oxides are common catalysts for industrial processes, e.g. the Claus process for converting hydrogen sulfide to sulfur in refineries and for the alkylation of amines. Many industrial catalysts are “supported”, meaning generally that an expensive catalyst (e.g., platinum) is dispersed over a high surface area material such as alumina. Being a very hard material (Mohs hardness 9), alumina is widely used as an abrasive and the production of applications that exploit its inertness, e.g., in high pressure sodium lamps.

Sulfates

Several sulfates of aluminium find applications. Aluminium sulfate (Al2(SO4)3(H2O)18) is produced on the annual scale of several billions of kilograms. About half of the production is consumed in water treatment. The next major application is in the manufacture of paper. It is also used as a mordant, in fire extinguisher, as a food additive, in fireproofing, and in leather tanning. Aluminium ammonium sulfate ([Al(NH4)](SO4)2)(H2O)12, also called ammonium alum, is used as a mordant and in leather tanning.[6] Aluminium potassium sulfate ([Al(K)](SO4)2)(H2O)12 is used similarly. The consumption of both alums is declining.

Chlorides

Aluminium chloride (AlCl3) is used in petroleum refining and in the production of synthetic rubber and polymers. Although it has a similar name, aluminium chlorohydrate has fewer and very different applications, e.g. as an hardening agent and an antiperspirant. It is an intermediate in the production of aluminium metal.

Niche compounds

Given the scale of aluminium compounds, a small scale application could still involve thousands of tons. One of the many compounds used at this intermediate level include aluminium acetate, a salt used in solution as an astringent. Aluminium borate (Al2O3 B2O3) is used in the production of glass and ceramics. Aluminium fluorosilicate (Al2(SiF6)3) is used in the production of synthetic gemstones, glass and ceramic. Aluminium phosphate (AlPO4) is used in the manufacture: of glass and ceramic, pulp and paper products, cosmetics, paints and varnishes and in making dental cement. Aluminium hydroxide (Al(OH)3) is used as an antacid, as a mordant, in water purification, in the manufacture of glass and ceramic and in the waterproofing of fabrics. Lithium aluminium hydride is a powerful reducing agent used in organic chemistry

Aluminium alloys in structural applications

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is Aluminium bronze (CuAl5).

History

The statue of the Anteros (commonly mistaken for either The Angel of Christian Charity or Eros) in Piccadilly Circus, London, was made in 1893 and is one of the first statues to be cast in aluminium.

Ancient Greeks and Romans used aluminium salts as dyeing mordants and as astringents for dressing wounds; alum is still used as a styptic. In 1761, Guyton de Morveau suggested calling the base alum alumine. In 1808, Humphry Davy identified the existence of a metal base of alum, which he at first termed alumium and later aluminum (see etymology section, below).

The metal was first produced in 1825 (in an impure form) by Danish physicist and chemist Hans Christian Ørsted. He reacted anhydrous aluminium chloride with potassium amalgam and yielded a lump of metal looking similar to tin.[42] Friedrich Wöhler was aware of these experiments and cited them, but after redoing the experiments of Ørsted he concluded that this metal was pure potassium. He conducted a similar experiment in 1827 by mixing anhydrous aluminium chloride with potassium and yielded aluminium.[42] Wöhler is generally credited with isolating aluminium (Latin alumen, alum), but also Ørsted can be listed as its discoverer.[43] Further, Pierre Berthier discovered aluminium in bauxite ore and successfully extracted it.[44] Frenchman Henri Etienne Sainte-Claire Deville improved Wöhler’s method in 1846, and described his improvements in a book in 1859, chief among these being the substitution of sodium for the considerably more expensive potassium.[45] Deville likely also conceived the idea of the electrolysis of aluminium oxide dissolved in cryolite; Charles Martin Hall and Paul Héroult might have developed the more practical process after Deville.

Before the Hall-Héroult process was developed, aluminium was exceedingly difficult to extract from its various ores. This made pure aluminium more valuable than gold.[46] Bars of aluminium were exhibited at the Exposition Universelle of 1855.[47] Napoleon III, Emperor of France, is reputed to have given a banquet where the most honoured guests were given aluminium utensils, while the others made do with gold.[48][49] The Washington Monument was completed, with the 100 ounce (2.8 kg) aluminium capstone being put in place on December 6, 1884, in an elaborate dedication ceremony. It was the largest single piece of aluminium cast at the time, when aluminium was as expensive as silver.[50] Aluminium has been produced in commercial quantities for just over 100 years.

Aluminium was selected as the material to be used for the apex of the Washington Monument in 1884, a time when one ounce (30 grams) cost the daily wage of a common worker on the project;[51] aluminium was about the same value as silver.

The Cowles companies supplied aluminium alloy in quantity in the United States and England using smelters like the furnace of Carl Wilhelm Siemens by 1886.[52] Charles Martin Hall of Ohio in the U.S. and Paul Héroult of France independently developed the Hall-Héroult electrolytic process that made extracting aluminium from minerals cheaper and is now the principal method used worldwide. Hall’s process,[53] in 1888 with the financial backing of Alfred E. Hunt, started the Pittsburgh Reduction Company today known as Alcoa. Héroult’s process was in production by 1889 in Switzerland at Aluminium Industrie, now Alcan, and at British Aluminium, now Luxfer Group and Alcoa, by 1896 in Scotland.[54]

By 1895, the metal was being used as a building material as far away as Sydney, Australia in the dome of the Chief Secretary’s Building.

Many navies have used an aluminium superstructure for their vessels; the 1975 fire aboard USS Belknap that gutted her aluminium superstructure, as well as observation of battle damage to British ships during the Falklands War, led to many navies switching to all steel superstructures. The Arleigh Burke class was the first such U.S. ship, being constructed entirely of steel.

Aluminium wire was once widely used for domestic electrical wiring. Owing to corrosion-induced failures, a number of fires resulted. This dicontinuation thus illustrates one failed application of the otherwise highly useful metal.

In 2008, the price of aluminium peaked at $1.45/lb in July but dropped to $0.70/lb by December.[55]

Etymology

Two variants of the metal’s name are in current use, aluminium and aluminum (besides the obsolete alumium). The International Union of Pure and Applied Chemistry (IUPAC) adopted aluminium as the standard international name for the element in 1990 but, three years later, recognized aluminum as an acceptable variant. Hence their periodic table includes both.[56] IUPAC prefers the use of aluminium in its internal publications, although nearly as many IUPAC publications use the spelling aluminum.[57]

Most countries use the spelling aluminium. In the United States, the spelling aluminum predominates.[14][58] The Canadian Oxford Dictionary prefers aluminum, whereas the Australian Macquarie Dictionary prefers aluminium. In 1926, the American Chemical Society officially decided to use aluminum in its publications; American dictionaries typically label the spelling aluminium as a British variant.

The name aluminium derives from its status as a base of alum. It is borrowed from Old French; its ultimate source, alumen, in turn is a Latin word that literally means “bitter salt”.[59]

The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. The citation is from the journal Philosophical Transactions of the Royal Society of London: “Had I been so fortunate as to have obtained more certain evidences on this subject, and to have procured the metallic substances I was in search of, I should have proposed for them the names of silicium, alumium, zirconium, and glucium.”[60][61]

Davy settled on aluminum by the time he published his 1812 book Chemical Philosophy: “This substance appears to contain a peculiar metal, but as yet Aluminum has not been obtained in a perfectly free state, though alloys of it with other metalline substances have been procured sufficiently distinct to indicate the probable nature of alumina.”[62] But the same year, an anonymous contributor to the Quarterly Review, a British political-literary journal, in a review of Davy’s book, objected to aluminum and proposed the name aluminium, “for so we shall take the liberty of writing the word, in preference to aluminum, which has a less classical sound.”[63]

The -ium suffix conformed to the precedent set in other newly discovered elements of the time: potassium, sodium, magnesium, calcium, and strontium (all of which Davy isolated himself). Nevertheless, -um spellings for elements were not unknown at the time, as for example platinum, known to Europeans since the 16th century, molybdenum, discovered in 1778, and tantalum, discovered in 1802. The -um suffix is consistent with the universal spelling alumina for the oxide, as lanthana is the oxide of lanthanum, and magnesia, ceria, and thoria are the oxides of magnesium, cerium, and thorium respectively.

The spelling used throughout the 19th century by most U.S. chemists was aluminium, but common usage is less clear.[64] The aluminum spelling is used in the Webster’s Dictionary of 1828. In his advertising handbill for his new electrolytic method of producing the metal 1892, Charles Martin Hall used the -um spelling, despite his constant use of the -ium spelling in all the patents[53] he filed between 1886 and 1903.[65] It has consequently been suggested that the spelling reflects an easier to pronounce word with one fewer syllable, or that the spelling on the flier was a mistake. Hall’s domination of production of the metal ensured that the spelling aluminum became the standard in North America; the Webster Unabridged Dictionary of 1913, though, continued to use the -ium version.

Health concerns

| NFPA 704 |

|---|

| Fire diamond for aluminium shot |

Despite its natural abundance, aluminium has no known function in biology. It is remarkably nontoxic, aluminium sulfate having an LD50 of 6207 mg/kg (oral, mouse), which corresponds to 500 grams for a 80 kg person.[6] Despite the extremely low acute toxicity, the health effect of Al are of interest in view of the widespread occurrence of the element in the environment and in commerce.

Some toxicity can be traced to deposition in bone and the central nervous system, which is particularly increased in patients with reduced renal function. Because aluminium competes with calcium for absorption, increased amounts of dietary aluminium may contribute to the reduced skeletal mineralization (osteopenia) observed in preterm infants and infants with growth retardation. In very high doses, aluminium can cause neurotoxicity, and is associated with altered function of the blood-brain barrier.[66] A small percentage of people are allergic to aluminium and experience contact dermatitis, digestive disorders, vomiting or other symptoms upon contact or ingestion of products containing aluminium, such as deodorants or antacids. In those without allergies, aluminium is not as toxic as heavy metals, but there is evidence of some toxicity if it is consumed in excessive amounts.[67] Although the use of aluminium cookware has not been shown to lead to aluminium toxicity in general, excessive consumption of antacids containing aluminium compounds and excessive use of aluminium-containing antiperspirants provide more significant exposure levels. Studies have shown that consumption of acidic foods or liquids with aluminium significantly increases aluminium absorption,[68] and maltol has been shown to increase the accumulation of aluminium in nervous and osseus tissue.[69] Furthermore, aluminium increases estrogen-related gene expression in human breast cancer cells cultured in the laboratory.[70] The estrogen-like effects of these salts have led to their classification as a metalloestrogen.

The effects of aluminium in antiperspirants has been examined over the course of decades with little evidence of skin irritation.[6] Nonetheless, its occurrence in antiperspirants, dyes (such as aluminium lake), and food additives is controversial in some quarters. Although there is little evidence that normal exposure to aluminium presents a risk to healthy adults,[71] some studies point to risks associated with increased exposure to the metal.[72] Aluminium in food may be absorbed more than aluminium from water.[73] Some researchers have expressed concerns that the aluminium in antiperspirants may increase the risk of breast cancer,[74] and aluminium has controversially been implicated as a factor in Alzheimer’s disease.[75] The Camelford water pollution incident involved a number of people consuming aluminium sulfate. Investigations of the long-term health effects are still ongoing, but elevated brain aluminium concentrations have been found in post-mortem examinations of victims, and further research to determine if there is a link with cerebral amyloid angiopathy has been commissioned.[76]

According to The Alzheimer’s Society, the overwhelming medical and scientific opinion is that studies have not convincingly demonstrated a causal relationship between aluminium and Alzheimer’s disease.[77] Nevertheless, some studies, such as those on the PAQUID cohort,[78] cite aluminium exposure as a risk factor for Alzheimer’s disease. Some brain plaques have been found to contain increased levels of the metal.[79] Research in this area has been inconclusive; aluminium accumulation may be a consequence of the disease rather than a causal agent. In any event, if there is any toxicity of aluminium, it must be via a very specific mechanism, since total human exposure to the element in the form of naturally occurring clay in soil and dust is enormously large over a lifetime.[80][81] Scientific consensus does not yet exist about whether aluminium exposure could directly increase the risk of Alzheimer’s disease.[77]

Effect on plants

Aluminium is primary among the factors that reduce plant growth on acid soils. Although it is generally harmless to plant growth in pH-neutral soils, the concentration in acid soils of toxic Al3+ cations increases and disturbs root growth and function.[82][83][84][85]

Most acid soils are saturated with aluminium rather than hydrogen ions. The acidity of the soil is therefore a result of hydrolysis of aluminium compounds.[86] This concept of “corrected lime potential”[87] to define the degree of base saturation in soils became the basis for procedures now used in soil testing laboratories to determine the “lime requirement”[88] of soils.[89]

Wheat‘s adaptation to allow aluminium tolerance is such that the aluminium induces a release of organic compounds that bind to the harmful aluminium cations. Sorghum is believed to have the same tolerance mechanism. The first gene for aluminium tolerance has been identified in wheat. It was shown that sorghum’s aluminium tolerance is controlled by a single gene, as for wheat.[90] This is not the case in all plants.

See also

References

- ^ Aluminium monoxide

- ^ Aluminium iodide

- ^ Magnetic susceptibility of the elements and inorganic compounds, in Handbook of Chemistry and Physics 81st edition, CRC press.

- ^ “Pronunciation of aluminium – how to pronounce aluminium correctly”. Howjsay.com. 2006-10-29. http://www.howjsay.com/index.php?word=aluminium. Retrieved 2010-05-03.

- ^ Shakhashiri, Bassam Z.. “Chemical of the Week: Aluminum”. Science is Fun. http://scifun.chem.wisc.edu/chemweek/Aluminum/ALUMINUM.html. Retrieved 2007-08-28.

- ^ a b c d Otto Helmboldt, L. Keith Hudson, Chanakya Misra, Karl Wefers, Wolfgang Heck, Hans Stark, Max Danner, Norbert Rösch “Aluminum Compounds, Inorganic” in Ullmann’s Encyclopedia of Industrial Chemistry, 2007, Wiley-VCH, Weinheim. doi:10.1002/14356007.a01_527.pub2

- ^ a b Polmear, I. J. (1995). Light Alloys: Metallurgy of the Light Metals. Arnold. ISBN 9780340632079.

- ^ Dieter G. E. (1988). Mechanical Metallurgy. McGraw-Hill. ISBN 0070168938.

- ^ Macleod, H. A. (2001). Thin-film optical filters. CRC Press. pp. 158–159. ISBN 0750306882.

- ^ Cochran, John F. and Mapother, D. E. (1958). “Superconducting Transition in Aluminum”. Physical Review 111 (1): 132–142. doi:10.1103/PhysRev.111.132.

- ^ Cameron, A.G.W. (1957). “Stellar Evolution, Nuclear Astrophysics, and Nucleogenesis”. CRL-41. http://www.fas.org/sgp/eprint/CRL-41.pdf.

- ^ “Cosmogenic Isotopes and Aluminum”. http://www.onafarawayday.com/Radiogenic/Ch14/Ch14-6.htm.

- ^ Robert T. Dodd (1986). Thunderstones and Shooting Stars. Cambridge, Mass.: Harvard University Press. pp. 89–90. ISBN 0-674-89137-6.

- ^ a b c Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Oxford: Butterworth-Heinemann. ISBN 0080379419., p. 217

- ^ “Aluminum Mineral Data”. http://webmineral.com/data/Aluminum.shtml. Retrieved 2008-07-09.

- ^ a b Chen Z., Huang C.-Y., Zhao M., Yan W., Chien C.-W., Chen M., Yang H., Machiyama H. & Lin S. (2011). “Characteristics and possible origin of native aluminum in cold seep sediments from the northeastern South China Sea”. Journal of Asian Earth Sciences 40(1): 363-370. doi:doi:10.1016/j.jseaes.2010.06.006.

- ^ Guilbert, John M. and Carles F. Park (1986). The Geology of Ore Deposits. Freeman. pp. 774–795. ISBN 0-7167-1456-6.

- ^ John A. S. Green (2007). Aluminum recycling and processing for energy conservation and sustainability. Materials Park, Ohio: ASM International. p. 198. ISBN 0871708590. http://books.google.com/?id=t-Jg-i0XlpcC&pg=PA198.

- ^ William B. Frank, Warren E. Haupin, Robert K. Dawless, Douglas A. Granger, Maurice W. Wei, Kenneth J. Calhoun, Thomas B. Bonney “Aluminum” in Ullmann’s Encyclopedia of Industrial Chemistry, 2009, Wiley-VCH, Weinheim. doi:10.1002/14356007.a01_459.pub2

- ^ Totten, George E; Scott Mackenzie, D; Comercial), Marcel Dekker (Firma (2003-04-25). Handbook of aluminum: Alloy production and materials manufacturing. p. 40. ISBN 9780824748432. http://books.google.de/books?id=KpgTrFloOq0C&pg=PA40.

- ^ a b Emsley, John (2001). “Aluminium”. Nature’s Building Blocks: An A-Z Guide to the Elements. Oxford, UK: Oxford University Press. p. 24. ISBN 0198503407. http://books.google.com/?id=j-Xu07p3cKwC&pg=PA24.

- ^ a b British Geological Survey (2009). World Mineral Production 2003-2007. http://www.bgs.ac.uk/downloads/start.cfm?id=1388.

- ^ Christoph Schmitz, Josef Domagala, Petra Haag (2006). Handbook of aluminium recycling: fundamentals, mechanical preparation, metallurgical processing, plant design. Vulkan-Verlag GmbH. p. 27. ISBN 3802729366.

- ^ “The Australian Industry”. Australian Aluminium Council. Archived from the original on 2007-07-17. http://web.archive.org/web/20070717041628/http://www.aluminium.org.au/Page.php?s=1005. Retrieved 2007-08-11.

- ^ “Australian Bauxite”. Australian Aluminium Council. Archived from the original on 2007-07-18. http://web.archive.org/web/20070718172244/http://www.aluminium.org.au/Page.php?s=1007. Retrieved 2007-08-11.

- ^ “Benefits of Recycling”. Ohio Department of Natural Resources. http://www.dnr.state.oh.us/recycling/awareness/facts/benefits.htm.

- ^ “Reciclado del aluminio. Confemetal.es ASERAL”. http://www.confemetal.es/aseral/recuperacion.htm.

- ^ Hwang, J.Y., Huang, X., Xu, Z. (2006). “Recovery of Metals from Aluminium Dross and Salt cake”. Journal of Minerals & Materials Characterization & Engineering 5: 47.

- ^ “Why are dross & saltcake a concern?”. http://www.ohiolandfills.org/faq/aluminium-dross-saltcake/.

- ^ Dunster, A.M., Moulinier, F., Abbott, B., Conroy, A., Adams, K., Widyatmoko, D.(2005). Added value of using new industrial waste streams as secondary aggregates in both concrete and asphalt. DTI/WRAP Aggregates Research Programme STBF 13/15C. The Waste and Resources Action Programme.

- ^ Elschenbroich, C. ”Organometallics” (2006) Wiley-VCH: Weinheim. ISBN 978-3-29390-6

- ^ a b Dohmeier, C.; Loos, D.; Schnöckel, H. (1996). “Aluminum(I) and Gallium(I) Compounds: Syntheses, Structures, and Reactions”. Angewandte Chemie International Edition 35 (2): 129. doi:10.1002/anie.199601291.

- ^ Tyte, D. C. (1964). “Red (B2Π–A2σ) Band System of Aluminium Monoxide”. Nature 202 (4930): 383. doi:10.1038/202383a0.

- ^ Merrill, P. W., Deutsch, A. J., & Keenan, P. C. (1962). “Absorption Spectra of M-Type Mira Variables”. Astrophysical Journal 136: 21. Bibcode 1962ApJ…136…21M. doi:10.1086/147348.

- ^ Werner Uhl, “Organoelement Compounds Possessing Al—Al, Ga—Ga, In—In, and Tl—Tl Single Bonds” Advances in Organometallic Chemistry Volume 51, 2004, Pages 53-108. doi:10.1016/S0065-3055(03)51002-4

- ^ “aluminum”. Encyclopædia Britannica. http://www.britannica.com/eb/art-64454.

- ^ Hetherington, L E et al. (2007) (available online). World Mineral Production: 2001–2005. British Geological Survey. ISBN 978-0-85272-592-4. http://www.bgs.ac.uk/downloads/start.cfm?id=1417.

- ^ Rising Chinese Costs to Support Aluminum Prices Bloomberg News, November 23, 2009

- ^ Millberg, L. S.. “Aluminum Foil”. How Products are Made. http://www.madehow.com/Volume-1/Aluminum-Foil.html. Retrieved 2007-08-11.

- ^ “Aluminum in Watchmaking”. http://watches.infoniac.com/index.php?page=post&id=62. Retrieved 2009-06-06.

- ^ “World’s coinage uses 24 chemical elements”, 2 part series, World Coin News (February 17, 1992 and March 2, 1992)

- ^ a b Wöhler, Friedrich. “Ueber das Aluminium”. Annalen der Physik und Chemie. http://gallica.bnf.fr/ark:/12148/bpt6k150967/f158.table.

- ^ Bentor, Yinon. “Periodic Table: Aluminum”. ChemicalElements.com. http://www.chemicalelements.com/elements/al.html. Retrieved 2007-08-11.

- ^ “Pierre Berthier”. Today in Science History. http://www.todayinsci.com/7/7_03.htm#Berthier. Retrieved 2007-08-11.

- ^ Henri Etienne Sainte-Claire Deville De l’aluminium, ses propriétés, sa fabrication (Paris, 1859)

- ^ Polmear, I.J. (2006). “Production of Aluminium”. Light alloys from traditional alloys to nanocrystals. Oxford: Elsevier/Butterworth-Heinemann. pp. 15–16. ISBN 9780750663717. http://books.google.com/?id=td0jD4it63cC&pg=PT29.

- ^ Karmarsch, Carl (1864). “Fernerer Beitrag zur Geschichte des Aluminiums”. Polytechnisches Journal 171 (1). http://books.google.com/?id=v4MtAAAAYAAJ&pg=PA49.

- ^ S Venetski (1969). “”Silver” from clay”. Metallurgist 13 (7): 451. doi:10.1007/BF00741130.

- ^ ChemMatters October 1990 p. 14.

- ^ G. J. Binczewski (1995). “The Point of a Monument: A History of the Aluminum Cap of the Washington Monument”. JOM 47: 20. http://www.tms.org/pubs/journals/JOM/9511/Binczewski-9511.html.

- ^ George J. Binczewski (1995). “The Point of a Monument: A History of the Aluminum Cap of the Washington Monument”. JOM 47 (11): 20–25. http://www.tms.org/pubs/journals/JOM/9511/Binczewski-9511.html.

- ^ “Cowles’ Aluminium Alloys”. The Manufacturer and Builder (New York: Western and Company, via Cornell University Library) 18 (1): 13. 1886. http://moa.cit.cornell.edu/cgi-bin/moa/pageviewer?frames=1&coll=moa&view=50&root=%2Fmoa%2Fmanu%2Fmanu0018%2F&tif=00019.TIF. Retrieved 2007-10-27. and McMillan, Walter George (1891). A Treatise on Electro-Metallurgy. London, Philadelphia: Charles Griffin and Company, J.B. Lippincott Company, via Google Books scan of New York Public Library copy. pp. 302–305. http://books.google.com/?id=DDAKAAAAIAAJ&pg=PA302. Retrieved 2007-10-26. and Sackett, William Edgar, John James Scannell and Mary Eleanor Watson (1917-19-18). New Jersey’s First Citizens. New Jersey: J.J. Scannell via Google Books scan of New York Public Library copy. pp. 103–105. http://books.google.com/?id=cNgDAAAAYAAJ&pg=PA103. Retrieved 2007-10-25.

- ^ a b US patent 400664, Charles Martin Hall, “Process of Reducing Aluminium from its Fluoride Salts by Electrolysis”, issued 1889-04-02

- ^ Wallace, Donald Holmes (1977) [1937]. Market Control in the Aluminum Industry. Harvard University Press via Ayer Publishing via Google Books limited view. p. 6. ISBN 0-4050-9786-7. http://books.google.com/?id=E-acdJWbo90C&pg=PA6. Retrieved 2007-10-27.

- ^ Aluminum prices.

- ^ IUPAC Periodic Table of the Elements.

- ^ IUPAC Web site publication search for ‘aluminum’.

- ^ Bremner, John Words on Words: A Dictionary for Writers and Others Who Care about Words, pp. 22–23. ISBN 0-231-04493-3.

- ^ “Online Etymology Dictionary”. Etymonline.com. http://www.etymonline.com/index.php?search=Alum&searchmode=none. Retrieved 2010-05-03.

- ^ “alumium”, Oxford English Dictionary. Ed. J.A. Simpson and E.S.C. Weiner, second edition Oxford: Clarendon Press, 1989. OED Online Oxford University Press. Accessed 29 October 2006. Citation is listed as “1808 SIR H. DAVY in Phil. Trans. XCVIII. 353”. The ellipsis in the quotation is as it appears in the OED citation.

- ^ Davy, Humphry (1808). “Electro Chemical Researches, on the Decomposition of the Earths; with Observations on the Metals obtained from the alkaline Earths, and on the Amalgam procured from Ammonia”. Philosophical Transactions of the Royal Society of London (Royal Society of London.) 98: 353. http://books.google.com/?id=Kg9GAAAAMAAJ&pg=RA1-PA353. Retrieved 2009-12-10.

- ^ Davy, Humphry (1812). Elements of Chemical Philosophy. ISBN 0217889476. http://books.google.com/?id=d6Y5AAAAcAAJ&pg=PA355. Retrieved 2009-12-10.

- ^ “Elements of Chemical Philosophy By Sir Humphry Davy”. Quarterly Review (John Murray) VIII: 72. 1812. ISBN 0217889476. http://books.google.com/?id=uGykjvn032IC&pg=PA72. Retrieved 2009-12-10.

- ^ Quinion, Michael (December 16, 2000). “ALUMINIUM VERSUS ALUMINUM: Why two spellings?”. World Wide Words. http://www.worldwidewords.org/articles/aluminium.htm., “In the USA, the position was more complicated. Noah Webster’s Dictionary of 1828 has only aluminum, though the standard spelling among US chemists throughout most of the nineteenth century was aluminium; it was the preferred version in The Century Dictionary of 1889 and is the only spelling given in the Webster Unabridged Dictionary of 1913.”

- ^ Meiers, Peter. “Manufacture of Aluminum”. The History of Fluorine, Fluoride and Fluoridation. http://www.fluoride-history.de/p-aluminum.htm.

- ^ Banks, W.A.; Kastin, AJ (1989). “Aluminum-induced neurotoxicity: alterations in membrane function at the blood-brain barrier”. Neurosci Biobehav Rev 13 (1): 47–53. doi:10.1016/S0149-7634(89)80051-X. PMID 2671833.

- ^ Abreo, V.. “The Dangers of Aluminum Toxicity”. http://www.bellaonline.com/articles/art7739.asp. Retrieved 2009-05-05.

- ^ Slanina, P.; Frech, W; Ekström, LG; Lööf, L; Slorach, S; Cedergren, A (1 March 1986). “Dietary citric acid enhances absorption of aluminum in antacids”. Clinical Chemistry (American Association for Clinical Chemistry) 32 (3): 539–541. PMID 3948402. http://www.clinchem.org/cgi/content/abstract/32/3/539. Retrieved 2008-10-09.

- ^ Van Ginkel, MF; Van Der Voet, GB; D’haese, PC; De Broe, ME; De Wolff, FA (1993). “Effect of citric acid and maltol on the accumulation of aluminum in rat brain and bone”. The Journal of laboratory and clinical medicine 121 (3): 453–60. PMID 8445293.

- ^ Darbre, P. D. (2006). “Metalloestrogens: an emerging class of inorganic xenoestrogens with potential to add to the oestrogenic burden of the human breast”. Journal of Applied Toxicology 26 (3): 191–7. doi:10.1002/jat.1135. PMID 16489580.

- ^ Gitelman, H. J. “Physiology of Aluminum in Man”, in Aluminum and Health, CRC Press, 1988, ISBN 0824780264, p. 90

- ^ Ferreira, PC; Piai Kde, A; Takayanagui, AM; Segura-Muñoz, SI (2008). “Aluminum as a risk factor for Alzheimer’s disease”. Revista latino-americana de enfermagem 16 (1): 151–7. doi:10.1590/S0104-11692008000100023. PMID 18392545.

- ^ Yokel RA, Hicks CL, Florence RL (2008). “Aluminum bioavailability from basic sodium aluminum phosphate, an approved food additive emulsifying agent, incorporated in cheese”. Food and chemical toxicology 46 (6): 2261–6. doi:10.1016/j.fct.2008.03.004. PMC 2449821. PMID 18436363.

- ^ Exley C, Charles LM, Barr L, Martin C, Polwart A, Darbre PD (2007). “Aluminium in human breast tissue”. J. Inorg. Biochem. 101 (9): 1344–6. doi:10.1016/j.jinorgbio.2007.06.005. PMID 17629949.

- ^ Ferreira PC, Piai Kde A, Takayanagui AM, Segura-Muñoz SI (2008). “Aluminum as a risk factor for Alzheimer’s disease”. Rev Lat Am Enfermagem 16 (1): 151–7. doi:10.1590/S0104-11692008000100023. PMID 18392545. http://www.scielo.br/scielo.php?script=sci_arttext&pid=S0104-11692008000100023&lng=en&nrm=iso&tlng=en.

- ^ Hawkes, Nigel (2006-04-20). “Alzheimers linked to aluminium pollution in tap water”. The Times (London). http://www.timesonline.co.uk/tol/news/uk/health/article707311.ece. Retrieved 2010-04-07.

- ^ a b Aluminium and Alzheimer’s disease, The Alzheimer’s Society. Retrieved 30 January 2009.

- ^ Rondeau, V.; Jacqmin-Gadda, H.; Commenges, D.; Helmer, C.; Dartigues, J.-F. (2008). “Aluminum and Silica in Drinking Water and the Risk of Alzheimer’s Disease or Cognitive Decline: Findings From 15-Year Follow-up of the PAQUID Cohort”. American Journal of Epidemiology 169 (4): 489–96. doi:10.1093/aje/kwn348. PMC 2809081. PMID 19064650.

- ^ Yumoto, Sakae; Kakimi, Shigeo; Ohsaki, Akihiro; Ishikawa, Akira (2009). “Demonstration of aluminum in amyloid fibers in the cores of senile plaques in the brains of patients with Alzheimer’s disease”. Journal of Inorganic Biochemistry 103 (11): 1579–84. doi:10.1016/j.jinorgbio.2009.07.023. PMID 19744735.

- ^ “Alzheimer’s Disease and Aluminum”. National Institute of Environmental Health Sciences. 2005. http://www.niehs.nih.gov/external/faq/aluminum.htm.

- ^ Hopkin, Michael (21 April 2006). “Death of Alzheimer victim linked to aluminium pollution”. news @ nature.com. doi:10.1038/news060417-10.

- ^ Belmonte Pereira, Luciane; Aimed Tabaldi, Luciane; Fabbrin Gonçalves, Jamile; Jucoski, Gladis Oliveira; Pauletto, Mareni Maria; Nardin Weis, Simone; Texeira Nicoloso, Fernando; Borher, Denise et al. (2006). “Effect of aluminum on δ-aminolevulinic acid dehydratase (ALA-D) and the development of cucumber (Cucumis sativus)”. Environmental and experimental botany 57 (1-2): 106–115. http://cat.inist.fr/?aModele=afficheN&cpsidt=17788836.

- ^ Andersson, Maud (1988). “Toxicity and tolerance of aluminium in vascular plants”. Water, Air, & Soil Pollution 39 (3–4): 439–462. http://www.springerlink.com/content/pxp793217612t333/.

- ^ Horst, Walter J. (1995). “The role of the apoplast in aluminium toxicity and resistance of higher plants: A review”. Zeitschrift für Pflanzenernährung und Bodenkunde 158 (5): 419–428. doi:10.1002/jpln.19951580503.

- ^ Ma, Jian Feng; Ryan, PR; Delhaize, E (2001). “Aluminium tolerance in plants and the complexing role of organic acids”. Trends in Plant Science 6 (6): 273–278. doi:10.1016/S1360-1385(01)01961-6. PMID 11378470.

- ^ Turner, R.C. and Clark J.S. (1966). “Lime potential in acid clay and soil suspensions”. Trans. Comm. II & IV Int. Soc. Soil Science: 208–215.

- ^ “corrected lime potential (formula)”. Sis.agr.gc.ca. 2008-11-27. http://sis.agr.gc.ca/cansis/glossary/corrected_lime_potential.html. Retrieved 2010-05-03.

- ^ Turner, R.C. (1965). “A Study of the Lime Potential”. Research Branch, Department Of Agriculture. http://journals.lww.com/soilsci/Citation/1965/07000/A_Study_of_the_Lime_Potential__5__Significance_of.3.aspx.

- ^ Applying lime to soils reduces the Aluminum toxicity to plants. “One Hundred Harvests Research Branch Agriculture Canada 1886–1986”. Historical series / Agriculture Canada – Série historique / Agriculture Canada. Government of Canada. http://epe.lac-bac.gc.ca/100/205/301/ic/cdc/agrican/pubweb/hs270060.asp. Retrieved 2008-12-22.

- ^ Magalhaes, J. V.; Garvin, DF; Wang, Y; Sorrells, ME; Klein, PE; Schaffert, RE; Li, L; Kochian, LV (2004). “Comparative Mapping of a Major Aluminum Tolerance Gene in Sorghum and Other Species in the Poaceae”. Genetics 167 (4): 1905. doi:10.1534/genetics.103.023580. PMC 1471010. PMID 15342528.

External links

- WebElements.com – Aluminium

- Electrolytic production

- World production of primary aluminium, by country

- Price history of aluminum, according to the IMF

- History of Aluminium (from the website of the International Aluminium Institute)

- Emedicine – Aluminium

|

|||||

| Periodic table | ||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | He | |||||||||||||||||||||||||||||||||||||||||

| Li | Be | B | C | N | O | F | Ne | |||||||||||||||||||||||||||||||||||

| Na | Mg | Al | Si | P | S | Cl | Ar | |||||||||||||||||||||||||||||||||||

| K | Ca | Sc | Ti | V | Cr | Mn | Fe | Co | Ni | Cu | Zn | Ga | Ge | As | Se | Br | Kr | |||||||||||||||||||||||||

| Rb | Sr | Y | Zr | Nb | Mo | Tc | Ru | Rh | Pd | Ag | Cd | In | Sn | Sb | Te | I | Xe | |||||||||||||||||||||||||

| Cs | Ba | La | Ce | Pr | Nd | Pm | Sm | Eu | Gd | Tb | Dy | Ho | Er | Tm | Yb | Lu | Hf | Ta | W | Re | Os | Ir | Pt | Au | Hg | Tl | Pb | Bi | Po | At | Rn | |||||||||||

| Fr | Ra | Ac | Th | Pa | U | Np | Pu | Am | Cm | Bk | Cf | Es | Fm | Md | No | Lr | Rf | Db | Sg | Bh | Hs | Mt | Ds | Rg | Cn | Uut | Uuq | Uup | Uuh | Uus | Uuo | |||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||

This information originally retrieved from http://en.wikipedia.org/wiki/Aluminum

on Monday 8th August 2011 9:06 pm EDT

Now edited and maintained by ManufacturingET.org